Compressed Air Desiccant Air Dryers - North Carolina and South Carolina

Remove excessive moisture in your compressed air systems!

In industrial operations, moisture in compressed air equipment can result in unexpected failure, frozen air lines, corrosion, quality control problems, and a host of other issues. Keeping your operations clean and up and running is essential. Desiccant air dryer systems from ESA can help purify compressed air by absorbing excess moisture.

What Are the Benefits Of Desiccant Air Dryers?

Industrial air compression systems need clean, dry air to operate effectively. Desiccant dryers are the solution to maintaining high air quality in compressed air systems. Some of the other benefits of desiccant air dryers include the following:

Because desiccant air dryers utilize the adsorption capabilities of desiccant material rather than using cooling to remove moisture, they are more energy efficient. Additionally, because they don’t use a large amount of power, they are a greener option for compressed air treatment.

Desiccant dryers only require occasional checks and desiccant material replacement to operate effectively. They tend to have a long lifespan – some go on for many years.

Desiccant air dryers have a relatively low cost of ownership. The energy efficiency, low-maintenance requirements, and affordability make them a cost-effective component of compressed air systems.

There are different types of desiccant air dryers, so you can choose the type that is ideal for your system and application.

Desiccant air dryers run continuously to supply a steady supply of clean, dry air. This helps reduce downtime caused by moisture within the system.

Overall, the benefits of using a desiccant air dryer from ESA make us the perfect choice for industrial companies that want to save on costs while maximizing efficiency.

What Are the Different Types of Desiccant Air Dryers?

Desiccant air dryers are also referred to as regenerative desiccant dryers or adsorption dryers. There are several different types of desiccant dryers, including the following:

Heatless Desiccant Dryers

The most common type of desiccant air dryer, this system uses a small amount of expanded compressed air to purge moisture from the desiccant. Heatless desiccant air dryers are best suited for applications with lower airflow.

Externally Heated Purge Dryers

The externally heated purge air dryer heat and blow air across the desiccant to dry it. The heated air can hold more moisture and cook off some liquid water. Because the air is heated, it reduces the amount of purge air and, therefore, reduces electricity consumption by about 25 percent (compared to heatless dryers).

Blower Purge Dryers

These desiccant air dryers force air through the desiccant to eliminate moisture. This prepares the off-line tower for the next cycle using regeneration. These dryers are typically more expensive than heated and heatless dryers but are also usually well worth the extra investment.

Heat of Compression Dryers

The heat of compression dryer regenerates desiccant with the heat that is naturally given off by the compressor, consuming no additional energy.

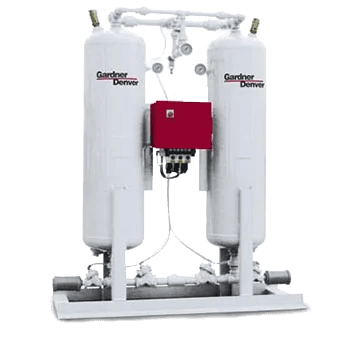

Dual Tower Dryers

Dual tower dryers use pressure swing adsorption (PSA) to dehumidify compressed air. This unique method allows the dryer to stop and start with a compressor to reduce purge loss.

Single Tower Dryers

Single-tower dryers are ideal for smaller, more specialized applications in which a continuous supply of clean and dry compressed air isn’t required.

Get the Details About Desiccant Air Dryers from ESA

It is nearly impossible to produce moisture-free air for industrial applications from ambient environments. However, failing to remove excess moisture from compressed air systems used in industrial settings lowers the process air quality and can damage moisture-sensitive equipment.

Desiccant, or adsorption, compressed air dryer systems are pieces of industrial equipment that use desiccant materials to remove moisture from the air that flows through them. Essentially, compressed air is purified as it is channeled through adsorbent material (desiccant) that has a high affinity for water. The adsorbent material maintains a dry immediate environment by holding water molecules within itself.

Protect Your Systems and Processes with an ESA Compressed Air Dryer

At ESA, we offer industrial compressed air dryers (both desiccant and refrigerated air dryers) to our industrial customers to maintain their controlled humidity environments. Industries in which the drying process is critical depend upon desiccant dryers to maintain the quality of their products.

If you need to maintain the compressed air quality in your compressed air system, ESA can help customers in North and South Carolina and surrounding areas. We offer 24-hour service, so we are available whenever you need us. Let us help you determine which type of compressed air treatment products will work best for you. Contact one of our experts today for all your compressed air needs.

The ESA Difference

Six decades of experience.

Superior customer service.

Trust through transparency. No hidden costs.

Preventive maintenance and repair experts.