You may have heard your ESA service technician mention that you need an oil water separator or that it’s time to change yours out. We wanted you to be informed on what this means, why it’s important and how it works in your compressed air system.

What do they do?

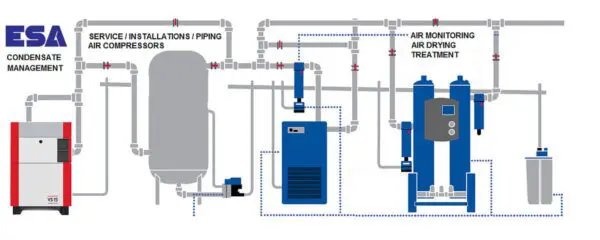

Through the process of compression, oil flooded air compressors produce hot compressed air with oil vapor, water vapor and other contaminants. Depending on the process of compression used (e.g. reciprocating, rotary screw), the compressed air temperature can exceed 200+ degrees F. To reduce the compressed air temperature and prevent potential damage to downstream equipment, the air temperature must be dropped typically by passing through a heat exchanger or aftercooler. The byproduct of this process causes the oil and water vapor to condense into liquid form. To properly dispose of this condensate liquid, the oil needs to be removed from the water so that the water can be disposed of in an environmentally safe and economical method through a drain to the municipal water system.

In other words, it separates oil from the water condensate so the oil can be collected and safely disposed of or recycled, while the remaining water with contaminants can pass to a traditional drainage system.

Why is an Oil-Water Separator necessary?

The US government states that water drained into the municipal system must have 40 PPM (Parts Per Million) or less of oil in the wastewater. Liquid that is dispensed from the dryer and/or pre-filtration & post-filtration usually contains approximately 300 PPM of oil to water (reference The Clean Water Act – EPA; CFR – Part 279, Title 40).

Without an oil-water separator in your compressed air system, the condensate / oil lubricant mixture will go down the drain and possibly find its way into the surrounding groundwater. If the oil contaminated condensate is disposed of by dumping it into a usual water system or collecting in a bucket and dumping outside, your company could have an unpleasant visit by EPA authorities.

How do they work?

For a compressed air process using a typical Oil / Water Separator, the oil-contaminated condensate can be fed under pressure to the Separator unit (1). The pressure is reduced in the pressure relief chamber (2) and with limited turbulence for more efficient extraction of oil droplets. In most instances, the condensate flows into an oleophilic filter system shown here to include a prefilter (4) and a main filter (5) for binding any residual oil constituents. The water flows out of the Oil / Water Separator through the water outlet (8) and can be discharged directly into the sewer system.

1 Condensate inlet

2 Pressure relief chamber

3 Level indicator

4 Prefilter

5 Main filter

6 Riser duct

7 Sampling valve

8 Water outlet

_______________________

For more information contact ESA.

Arthur Pue

Arthur Pue is the President of Engineering Sales Associates. Connect with him on LinkedIn.